EARTHING

INFORMATION & AWARENESS

WHAT IS EARTHING?

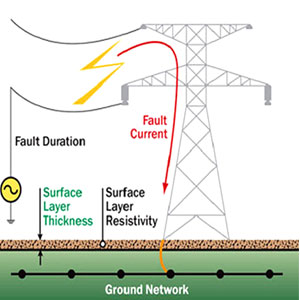

In electricity supply systems, an earthing system or grounding system is circuitry which connects parts of the electric circuit with the ground (electricity), thus defining the electrical potential of the conductors relative to the Earth's conductive surface.

FIRE !! WHAT ARE THE REASONS OF FIRE??

WHO IS RESPONSIBLE??

We are living in the era of machines and most of the machines works on electricity. Every thing is automatic and works we become a slave to electricity. Home and Industrial Electrification systems works on electricity. Use of more electrical appliances lead to use of more electricity, more load, more accidents. To prevent these fire accidents, we should be aware of causes of fire and follow some measures. Use of old wiring system is the main reason of fire. Using a fitting which is 25-50 years old lead to fire because now a days load has extended due to use of heavy machinery. This overload results in short-circuit and fire.

Except old wiring and Proper Load Inspection, the biggest reason is improper earthing. Uneducated electrician, Existing Deep Boring system using an aluminium wire instead of copper are some of the signs of improper earthing. This results of accident in the Home and Industry.

WHILE ADOPTING AN EARTHING SYSTEM:

The Number of earthing is depending on the requirement of load and machinery.

Causes of Electrical Fire:

TYPES OF EARTHING

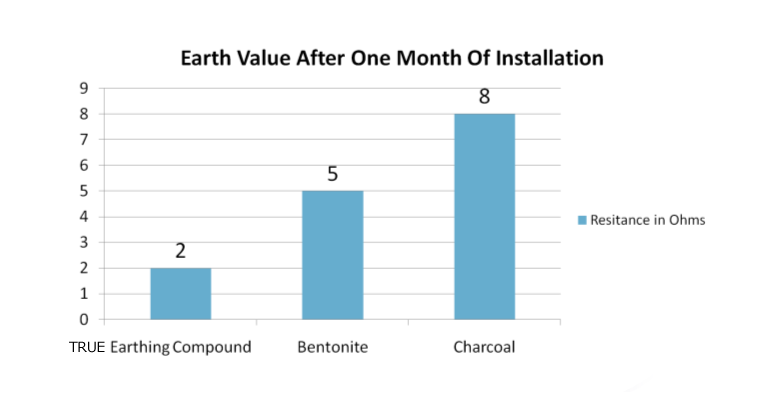

GEL/COMPOUND EARTHING:

TECHNICAL SPECIFICATIONS:

TECHNICAL SPECIFICATIONS:

EARTHING

EARTHING DESIGN FOR PRODUCT

EXAMPLES:

LIFE OF EARTHING

PRODUCTS WE OFFER

FEATURES:

2. There level protection from corrosive:-

a. External Pipe

b. High inductive crystalline chemical.

c. Primary conductor. (Copper/G.I.)

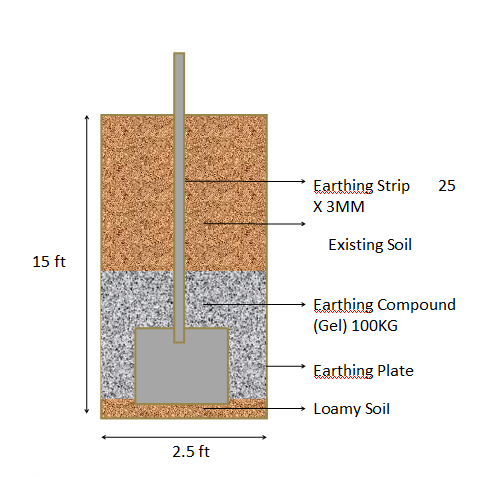

PROCESS OF INSTALLATION:

1. Mark the earthing place near to connecting point.2. Dig the place nearly 2'Ũ2' upto depth to 3ft. Then drill a bore of 4" dia in the centre of dig pit upto depth of 10-12 ft.

3. Unwrap the electrode properly and clean the complete surface of the electrode.

4. Connect the conducting wire/strip with the primary conduct of electrode. It should be connected with the help of nuts & bolts suitable for the metal used.

5. Now open the bag and put 10 kg of dry compound in the bore.

6. Insert the electrode in the bore keeping connected strip/wire end outside.

7. Mix the remaining 15 kg compound with 100 ltr of water and stir it well for about 10 min. It will take gel shape. Pour this gel in the bore and pit to fill it unto surface level.

8. Let it settle for 45 min. Your earthing is ready to use.

"DON'T ENTER IN THE HOUSE IF THE EARTHING IS NOT DONE"

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||